The

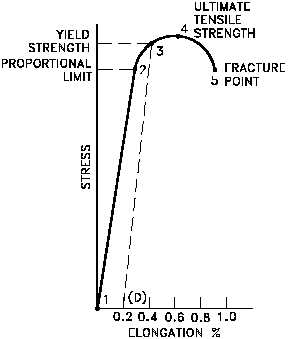

relationship between the stress and strain that a particular material

displays is known as that material's Stress-Strain curve.

Stress-strain curves of various materials vary widely, and different tensile tests conducted on the same material yield different results, depending upon the temperature of the specimen and the speed of the loading.

It is possible, however, to distinguish some common characteristics among the stress-strain curves of various groups of materials and, on this basis, to divide materials into two broad categories; namely, the ductile materials and the brittle materials.

The actual rupture point is in the same vertical line as the visual rupture point. However, beyond this point a neck forms where the local cross-sectional area decreases more quickly than the rest of the sample resulting in an increase in the true stress .

As shown in Fig.2, On an engineering stress–strain curve this is seen as a decrease in the apparent stress. However if the curve is plotted in terms of true stress and true strain the stress will continue to rise until failure.

Less ductile materials such as aluminum and medium to high carbon steels do not have a well-defined yield point.There are generally two types of yield points,upper and lower yield point.

For these materials the yield strength is typically determined by the "offset yield method", by which a line is drawn parallel to the linear elastic portion of the curve and intersecting the abscissa at some arbitrary value .

.

Stress-strain curves of various materials vary widely, and different tensile tests conducted on the same material yield different results, depending upon the temperature of the specimen and the speed of the loading.

It is possible, however, to distinguish some common characteristics among the stress-strain curves of various groups of materials and, on this basis, to divide materials into two broad categories; namely, the ductile materials and the brittle materials.

Tensile Stress

Taking this concept over, we say that the bar is under tension, and is experiencing a stress that we define to be the ratio of the force to the cross sectional area.Stress = F/A This stress is called the tensile stress because every part of the object is subjected to a tension.Ductile materials

Low carbon steel generally exhibits a very linear stress–strain relationship up to a well defined yield point .The actual rupture point is in the same vertical line as the visual rupture point. However, beyond this point a neck forms where the local cross-sectional area decreases more quickly than the rest of the sample resulting in an increase in the true stress .

As shown in Fig.2, On an engineering stress–strain curve this is seen as a decrease in the apparent stress. However if the curve is plotted in terms of true stress and true strain the stress will continue to rise until failure.

Less ductile materials such as aluminum and medium to high carbon steels do not have a well-defined yield point.There are generally two types of yield points,upper and lower yield point.

For these materials the yield strength is typically determined by the "offset yield method", by which a line is drawn parallel to the linear elastic portion of the curve and intersecting the abscissa at some arbitrary value .

Brittle materials

Brittle materials, which includes cast iron, glass, and stone, are

characterized by the fact that rupture occurs without any noticeable

prior change in the rate of elongation.One of the characteristics of a brittle failure is that the two broken

parts can be reassembled to produce the same shape as the original

component as there will not be a neck formation like in the case of

ductile materials.

No comments:

Post a Comment