Focused Ion-Beam Machining

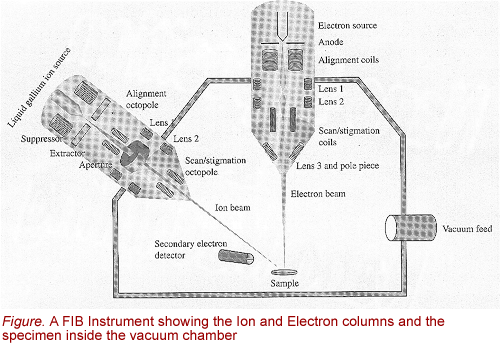

Focused ion beam, also known as FIB, is a technique used particularly in the semiconductor industry, materials science and increasingly in the biological field for site-specific analysis, deposition, and ablation of materials. An FIB setup is a scientific instrument that resembles a scanning electron microscope (SEM). However, while the SEM uses a focused beam of electrons to image the sample in the chamber, an FIB setup uses a focused beam of ions instead. FIB can also be incorporated in a system with both electron and ion beam columns, allowing the same feature to be investigated using either of the beams. FIB should not be confused with using a beam of focused ions for direct write lithography (such as in proton beam writing). These are generally quite different systems where the material is modified by other mechanisms.

click here to see video

Principle

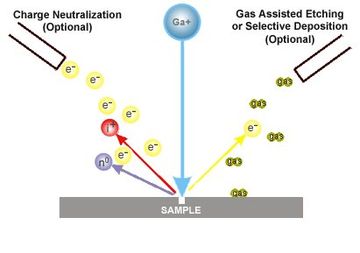

As the diagram on the right shows, the gallium (Ga+) primary ion beam hits the sample surface and sputters a small amount of material, which leaves the surface as either secondary ions (i+ or i-) or neutral atoms (n0). The primary beam also produces secondary electrons (e–). As the primary beam rasters on the sample surface, the signal from the sputtered ions or secondary electrons is collected to form an image.

At low primary beam currents, very little material is sputtered and modern FIB systems can easily achieve 5 nm imaging resolution (imaging resolution with Ga ions is limited to ~5 nm by sputtering and detector efficiency). At higher primary currents, a great deal of material can be removed by sputtering, allowing precision milling of the specimen down to a sub micrometre or even a nano scale.

Technology

Usage

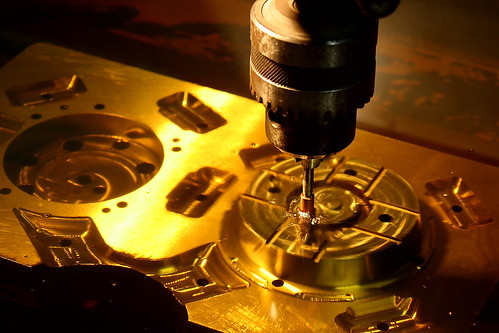

Unlike an electron microscope, FIB is inherently destructive to the specimen. When the high-energy gallium ions strike the sample, they will sputter atoms from the surface. Gallium atoms will also be implanted into the top few nanometers of the surface, and the surface will be made amorphous.Because of the sputtering capability, the FIB is used as a micro- and nano-machining tool, to modify or machine materials at the micro- and nanoscale. FIB micro machining has become a broad field of its own, but nano machining with FIB is a field that is still developing. Commonly the smallest beam size for imaging is 2.5–6 nm. The smallest milled features are somewhat larger (10–15 nm) as this is dependent on the total beam size and interactions with the sample being milled.

Helium ion microscope (HeIM)

Another ion source seen in commercially available instruments is a helium ion source, which is inherently less damaging to the sample than Ga ions although it will still sputter small amounts of material especially at high magnifications and long scan times. As helium ions can be focused into a small probe size and provide a much smaller sample interaction than high energy (>1 kV) electrons in the SEM, the He ion microscope can generate equal or higher resolution images with good material contrast and a higher depth of focus. Commercial instruments are capable of sub 1 nm resolution.

The applications of FIB include :

- cross-sectional imaging through semiconductor devices (or any layered structure)

- modification of the electrical routing on semiconductor devices

- failure analysis

- preparation for physico-chemical analysis

- preparation of specimens for transmission electron microscopy (TEM)

- preparation of samples for AtomProbe analysis

- micro-machining

- mask repair

- non-semiconductor applications

The acronym EDM is derived from Electrical Discharge Machining.

The acronym EDM is derived from Electrical Discharge Machining.

The

basic EDM process is really quite simple. An electrical spark is

created between an electrode and a work piece. The spark is visible

evidence of the flow of electricity. This electric spark produces

intense heat with temperatures reaching 8000 to 12000 degrees Celsius,

melting almost anything. The spark is very carefully controlled and

localized so that it only affects the surface of the material. The EDM

process usually does not affect the heat treat below the surface. With

wire EDM the spark always takes place in the dielectric of deionized

water. The conductivity of the water is carefully controlled making an

excellent environment for the EDM process. The water acts as a coolant

and flushes away the eroded metal particles.

The

basic EDM process is really quite simple. An electrical spark is

created between an electrode and a work piece. The spark is visible

evidence of the flow of electricity. This electric spark produces

intense heat with temperatures reaching 8000 to 12000 degrees Celsius,

melting almost anything. The spark is very carefully controlled and

localized so that it only affects the surface of the material. The EDM

process usually does not affect the heat treat below the surface. With

wire EDM the spark always takes place in the dielectric of deionized

water. The conductivity of the water is carefully controlled making an

excellent environment for the EDM process. The water acts as a coolant

and flushes away the eroded metal particles.