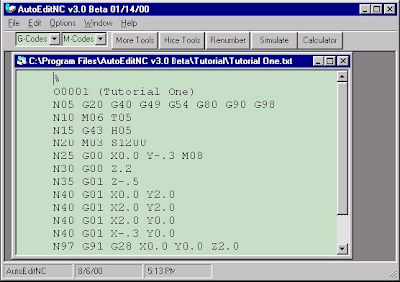

In modern CNC systems, end-to-end component design is highly automated using computer-aided design (CAD) and computer-aided manufacturing

(CAM) programs. The programs produce a computer file that is

interpreted to extract the commands needed to operate a particular

machine via a postprocessor, and then loaded into the CNC machines for

production.

Numerical control (NC) is the automation of machine tools that are operated by abstractly programmed commands encoded on a storage medium, as opposed to controlled manually via handwheels or levers, or mechanically automated via cams alone

Complex parts can be quickly and accurately programmed, over an extensive range of component types, in Catia V5 and subsequently verified in Vericut.

In modern CNC systems, end-to-end component design is highly automated using computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. The programs produce a computer file that is interpreted to extract the commands needed to operate a particular machine via a postprocessor, and then loaded into the CNC machines for production.

Within the numerical systems of CNC programming it is possible for the code generator to assume that the controlled mechanism is always perfectly accurate, or that accuracy tolerances are identical for all cutting or movement directions. This is not always a true condition of CNC tools. CNC tools with a large amount of mechanical backlash can still be highly accurate if the drive or cutting mechanism is only driven so as to apply cutting force from one direction, and all driving systems are pressed tight together in that one cutting direction.

Numerical control (NC) is the automation of machine tools that are operated by abstractly programmed commands encoded on a storage medium, as opposed to controlled manually via handwheels or levers, or mechanically automated via cams alone

Complex parts can be quickly and accurately programmed, over an extensive range of component types, in Catia V5 and subsequently verified in Vericut.

In modern CNC systems, end-to-end component design is highly automated using computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. The programs produce a computer file that is interpreted to extract the commands needed to operate a particular machine via a postprocessor, and then loaded into the CNC machines for production.

Within the numerical systems of CNC programming it is possible for the code generator to assume that the controlled mechanism is always perfectly accurate, or that accuracy tolerances are identical for all cutting or movement directions. This is not always a true condition of CNC tools. CNC tools with a large amount of mechanical backlash can still be highly accurate if the drive or cutting mechanism is only driven so as to apply cutting force from one direction, and all driving systems are pressed tight together in that one cutting direction.

No comments:

Post a Comment